China OEM Stainless Steel Flat Top Conveyor Chain Air Compressor Repair Near Me

Product Description

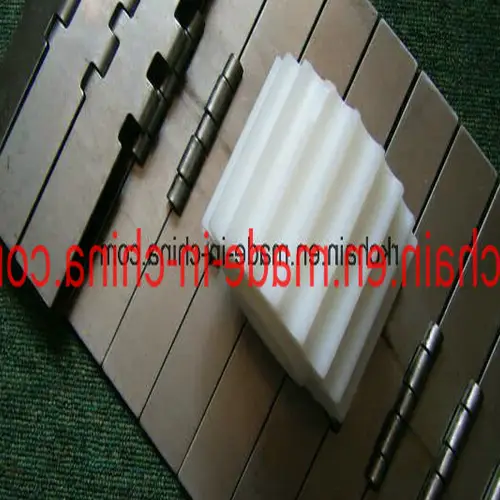

The Stainless Steel Flat Top Conveyor Chain is a durable and versatile chain that is ideal for various applications. It is available in different chain types, including:

820

- 820 K250

- 820 K325

- 820 K350

- 820 K400

- 820 K450

- 820 K600

- 820 K750

821

- 821 K750

- 821 K1000

- 821 K1200

880

- 880 K325

- 880 K450

880TAB

- 880 TAB K325

- 880 TAB K450

882 TAB

- 882 TAB K500

- 882 TAB K600

- 882 TAB K750

- 882 TAB K1000

- 882 TAB K1200

The Stainless Steel Flat Top Conveyor Chain is manufactured by our company, a leading supplier of modular belts, plastic top chains, stainless steel top chains, and other conveyor components. With our ISO 9001:2000 quality certificate, we ensure that our products meet the highest standards. Our products are trusted and used by customers in Europe, Middle East, America, and many other countries and regions.

Main Products

Our company specializes in supplying a full range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, flat top chains, pulleys, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service. We welcome customization requests and can work with drawings and samples to meet specific requirements.

Packaging & Shipping

Our products are carefully packaged to ensure safe delivery. We offer various shipping options to meet different needs and ensure timely arrival of orders.

Exhibition

We participate in industry exhibitions to showcase our products and connect with potential customers. We believe in building strong relationships and partnerships to support the growth and success of our customers.

Contact Us

If you have any questions or would like more information about our products, please feel free to contact us. We are here to assist you and provide prompt and helpful responses.

Frequently Asked Questions (FAQs)

1. What industries can benefit from using the Stainless Steel Flat Top Conveyor Chain?

The Stainless Steel Flat Top Conveyor Chain is suitable for a wide range of industries, including food processing, beverage production, pharmaceuticals, packaging, and more. Its durable construction and smooth operation make it an ideal choice for conveying various products.

2. Are customizations available for the chain?

Yes, we offer customization services to meet specific requirements. Whether you need a different chain length, additional attachments, or special coatings, we can work with you to create a chain that fits your unique needs.

3. What are the advantages of using a stainless steel chain?

Stainless steel chains offer excellent resistance to corrosion, high temperatures, and chemicals. They are also easy to clean and maintain, making them suitable for applications that require strict hygiene standards.

4. How can I ensure the longevity of the chain?

To ensure the longevity of the Stainless Steel Flat Top Conveyor Chain, regular maintenance is essential. This includes cleaning the chain, inspecting for any damage or wear, and lubricating it as recommended. Following proper maintenance procedures will help extend the chain’s lifespan.

5. Can I get a sample of the chain before making a purchase?

Yes, we offer samples of our products. Please contact us with your specific requirements, and we will be happy to assist you in obtaining a sample of the Stainless Steel Flat Top Conveyor Chain.

All the content of this page is from the Internet, and it is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

Performance Characteristics of Flat Top Chain

Flat top chains have several performance characteristics that make them ideal for various applications. Firstly, they have a high load-bearing capacity, making them suitable for heavy-duty operations. Secondly, they offer excellent wear resistance, ensuring durability and longevity. Additionally, flat top chains provide smooth and reliable conveying, minimizing disruptions in production processes. Their low friction coefficient reduces energy consumption, making them energy-efficient. Moreover, these chains have a low noise level, ensuring a quiet working environment. Finally, they are easy to install and maintain, providing convenience for users.

Types and Characteristics of Flat Top Chain

Flat top chains come in various types, each with its own unique characteristics. One common type is the straight-running flat top chain, which is ideal for applications that require straight conveying paths. Another type is the side-flexing flat top chain, designed for curved conveyor systems. This type offers flexibility and smooth movement around bends. Additionally, there are modular flat top chains that are easily customizable to suit specific requirements. These chains can be easily assembled and disassembled, allowing for quick and efficient maintenance.

Advantages of Flat Top Chain Made of Different Materials

Flat top chains can be made of different materials, each providing distinct advantages. Chains made of stainless steel offer high corrosion resistance, making them suitable for applications in corrosive environments. Plastic flat top chains are lightweight and have excellent chemical resistance, making them ideal for industries that require strict hygiene standards. Meanwhile, chains made of carbon steel provide high strength and durability, making them suitable for heavy-duty applications. The choice of material depends on the specific requirements of the application.

Application of Flat Top Chain in Various Industries

Flat top chains find wide application in various industries, highlighting their value and importance. In the Pharmaceutical Industry, these chains are used for conveying medication bottles, blister packs, and other pharmaceutical products. In the Packaging Industry, flat top chains are utilized for the smooth and efficient movement of packages and containers. The Electronics Manufacturing industry relies on flat top chains for the precise and reliable handling of electronic components. In the Automotive Industry, these chains are used in assembly lines for the transportation of car parts. Flat top chains also play a crucial role in the Cosmetics Industry, ensuring the gentle handling of delicate cosmetic products. The versatility of flat top chains allows them to adapt to the specific needs of each industry, making them indispensable in various fields.

Future Development Trends and Opportunities

The future of flat top chain products is promising, with several development trends and opportunities on the horizon. As automation continues to advance, there will be an increased demand for efficient conveying systems, driving the growth of flat top chains. The integration of smart technologies, such as sensors and data analytics, will further enhance the performance and reliability of these chains. Additionally, the rising emphasis on sustainability and energy efficiency will drive the development of eco-friendly flat top chains. Opportunities for innovation and product enhancement are abundant in this evolving industry, making it an exciting space for growth and development.

How to Choose a Suitable Flat Top Chain

Choosing the right flat top chain involves considering several key factors. Firstly, it is important to determine the specific application requirements, such as load capacity and conveying speed. Secondly, identifying the type of chain needed, whether straight-running or side-flexing, is crucial for ensuring proper functionality. The selection of chain material should be based on the environmental conditions and industry requirements. Additionally, considering the chain dimensions, such as width and pitch, is essential for compatibility with existing conveyor systems. Lastly, checking the compatibility of the chosen chain with sprockets is necessary to ensure smooth operation. By carefully analyzing these aspects, one can select a suitable flat top chain that meets the specific needs of their application.

Summary

Flat top chains offer a range of performance characteristics that make them highly advantageous in various industries. They provide efficient conveying, high load-bearing capacity, and low maintenance requirements. The choice of material allows for customization and adaptation to different environments. From the Pharmaceutical Industry to the Cosmetics Industry, flat top chains play a vital role in ensuring smooth and reliable production processes. With future trends pointing towards automation and sustainability, the opportunities for flat top chain products are abundant. By considering application requirements, chain types, materials, dimensions, and compatibility with sprockets, one can choose the most suitable flat top chain for their specific needs.

Author: Dream